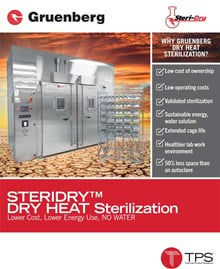

Your Partner in Developing Custom Industrial Oven Solutions

Need an oven that _________? No problem. We can do that!

At TPS, our engineering design services team will work with you to help turn your biggest thermal-processing challenges into business successes. We’ve collaborated with some of the largest and most well-known manufacturers in the medical, pharmaceutical, aerospace, technology, energy, electronics, consumer goods, and defense industries to develop innovative thermal-processing solutions designed to achieve the specific results our customers needed, while helping them avoid unwanted outcomes.

- Marinite construction for non-metallic and non-magnetic applications

- Break-away blast chambers for testing explosives

- Optics Conveyor Ovens for curing silicone hydrogel based lenses

- CHIL construction ensures minimum heat transfer from chamber to exterior

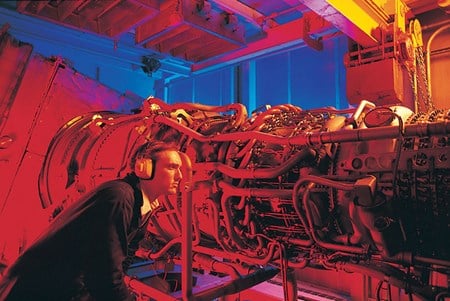

- Military and aerospace

- Consumer product testing

- Clean room applications

- Explosive and inert gas atmospheres

- High temperatures and vacuums

- Small footprint designs

- Robotic load/unload

- Web-based management

Design Possibilities? It’s Mission Possible, with a TPS Custom Solution.

Industry Applications: What’s HOT in Custom Design?

Innovation with a Reason: ROI

You don’t have money to burn. So, if you’re going to invest in a custom industrial oven that’s tailored to your specific process, you want to know before you buy that it will offer a good return on your investment. Our team will work with you to devise a smart and sensible solution you can’t afford to miss!

You don’t have money to burn. So, if you’re going to invest in a custom industrial oven that’s tailored to your specific process, you want to know before you buy that it will offer a good return on your investment. Our team will work with you to devise a smart and sensible solution you can’t afford to miss!

- Nitrogen feedback loop

- Impervious barrier between the process chamber and insulation material

- Top-mounted, solvent-condensing system

- Intrinsically safe, interior design

- Forced-air exhaust system

- Ambient-air intake port

- Pressure-relief panel

- Explosion-proof junction box

- Safety cage

- Semi-pierced, duct-wall construction

- Vertical-lift doors

- Pneumatically inflated door gaskets

- Inert atmosphere

- Chilled-water cooling system

- High-volume, horizontal airflow system

- Semi-pierced duct walls

- Removable, bolt-on, end panels.

- Guide rail system

- Energy-efficient, Incoloy® sheathed, tubular heaters

- Remote Chromolox fluid heat-transfer system

- Exhaust bypass system

- Solvent-recovery system

- Refrigerated evaporator cooling coil

- Vertical, counterweighted, pneumatically operated lift door on both sides

- High-volume, vertical-up controlled airflow

- Product carriers, with hooks

- Speed-controlled, conveyor-gear motor with a variable frequency drive

- Pneumatic can pusher

TPS Custom Ovens Team

Our expert team of engineers, technicians, and product specialists is here to help you design the custom oven that’s right for your application. Contact a member of our Custom Ovens Team to custom engineer a solution designed for your specific application that will keep you Design Solutions Custom Engineered for Your Specific Application.