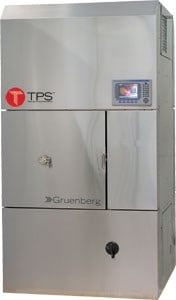

Sterilizers & Drying Ovens

TPS manufactures Gruenberg and Blue M ovens for medical device drying, pharmaceutical granulation drying, lab utensil sterilization, and more. Superior airflow and temperature capabilities ensure uniform moisture removal, while a range of models with HEPA filtration, NFPA 86 Class B or Class “A” with optional inert atmosphere features meet the toughest industry requirements and safety standards. Common products processed in a Gruenberg or Blue M dry heat sterilizers or drying oven includes glassware, metal instruments, granulation and medical devices.

Why Dry Heat?

Dry heat sterilization eliminates, removes, kills or deactivates all forms of life and other biological agents (such as fungi, bacteria, viruses, spore forms and prions) by raising the temperature of an item to above 320°F. Heated air or steam can be used in this process. Our lab sterilizers are ideal for laboratory and pharmaceutical applications.

Dry heat ovens have several advantages of steam autoclaves, including higher temperatures and the ability to sterilize materials that might be damaged to steam or are impenetrable to moist heat. It is the most effective sterilization method, with lower energy and cost. .

Dry Heat Sterilizers

Gruenberg’s dry heat sterilizers are the ideal solution for medical, pharmaceutical and life science research to decontaminate and sterilize all forms of microbial life including viruses and bacteria.

Chamber Size: 1.25 to 1000 cubic feet

Lab Animal Science Sterilizers

Gruenberg’s sterilizers use dry heat instead of steam in order to effectively sterilize laboratory animal equipment such as habitat cages.

Chamber Size: 10.8 to 362 cubic feet

Key Specifications

- Maximum Temperature Range: 340°F to 400°F

- Uniformity: ±5ºF

Granulation Dryers

Gruenberg manufactures and designs standard and custom granulation dryers that are ideal for pharmaceutical processes. For granulation drying processes that involve solvents, Gruenberg offers explosion resistant granulation dryers.

Chamber Size: 15 to 800 cubic feet

Key Specifications

- Maximum Temperature: 194°F for steam and 500°F for electric units

- Uniformity: dryer ±2°; dryer oven ±5°

Custom Pharmaceutical Ovens

Custom pharmaceutical industrial ovens for your drying and sterilization needs with capacities from 15 to 800 cubic feet. These hot air ovens can be built for a variety of operations with adjustable airflow velocities.

Chamber Size: 15 to 800 cubic feet

Truck In Ovens

Dependability and durability. Gruenberg manufactures truck-in and walk-in ovens that are suitable for manual loading as well as by fork truck.

Chamber Size: 12 to 480 cubic feet

Key Specifications

- Maximum Temperature Range: 450°F to 1200°F

Class 100 Ovens / Clean Room Ovens

Our Class 100 Clean Room Ovens provide the perfect clean environment for pharmaceutical manufacturing – eliminating any possibility for environmental pollutants like dust, microbes, and vapors from coming into contact with your product.

Chamber Size: 1.2 to 95.8 cubic feet

Key Specifications

- Temperature Range: 15°C to 350°C

- Standard Depyrogenation Rating: 260°C

- Control: +0.5°C

- Uniformity: ±1%

- Resolution: 0.1°C

- Run up time to 300°C: 60min.