Tenney ETCU Temperature / Humidity Cycling Test Chamber

The Tenney ETCU Ultimate Series Temperature Humidity Cycling Chamber features scroll compressor technology that provides quiet operation, fast transition rates, and reliable operations.

The chambers incorporate a ceiling plenum to diffuse conditioned air vertically through the chamber. The top-to-bottom air circulation guarantees stable and consistent performance over the testing period.

Multiple heating and cooling systems are available, as well as a diverse list of options that together will create the chamber to accommodate your specific application.

Benefits

- Scroll Compressors provide the Tenney ETCU Temperature / Humidity Cycling Test Chamber with quiet operation, fast transition rates, and reliable operations

- Vertical air circulation guarantees stable and consistent performance over testing periods

- Multiple heating and cooling systems and options are available to create a chamber that accommodates your specific application

- Uses environmentally friendly, HFC-free refrigerants and durable refrigeration systems

- Innovative vertically-hinged door provides operator with easy access to the work area

Features

- NEC compliant wiring

- Non-corroding parts on all humidity capable units

- Low water protection

- Open-air low mass nichrome wire heating elements supported by ceramic insulators

- Single or cascade type refrigeration system

- Vapor-Flo II Humidity Generator (when humidity system is employed)

- Dehumidify coil

- Vertical air flow system generated by centrifugal blower wheels

- Interior chamber made of stainless steel insulated by fiberglass insulation and foam insulation

Performance

Temperature ranges:

- With Single Stage Refrigeration: - 35°C to + 200°C, +/- 0.5 deg. after stabilization

- With Cascade Refrigeration System: - 73°C to + 200°C, +/- 0.5 deg. after stabilization

- Standard Humidity Range: 20% to 98% RH in the dry bulb range from +20°C to +85°C, limited by a dewpoint of +3°C

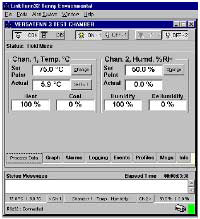

Controller

Options

Specifications

Cascade Refrigeration Specifications - Temperature Range: -70°C to 200°C

| Model | ETCU–09 | ETCU–16 | ETCU–30 | ETCU–64 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Interior Volume | 9 cu. ft. 256 liters |

16 cu. ft. 460 liters |

30 cu. ft. 850 liters |

64 cu. ft. 1,812 liters |

|||||||||||

| Interior Dimensions W x D x H in. (mm) |

24" x 25" x 26" / 610 x 635 x 660 | 36" x 26" x 30" / 914 x 660 x 762 | 40" x 36" x 36" / 1016 x 914 x 914 |

48" x 48" x 48" / 1219 x 1219 x 1219 |

|||||||||||

| Exterior Dimensions W x D x H in (mm) |

34" x 73" x 78" / 864 x 1854 x 1983 | 46" x 74" x 82" / 1169 x 1881 x 2084 | 50" x 87" x 88" / 1271 x 2211 x 2237 |

58" x 99" x 100" / 1474 x 2516 x 2542 |

|||||||||||

| Nominal Horsepower | 3.5 x 3.5 | 6 x 6 | 10 x 10 | 3.5 x 3.5 | 6 x 6 | 10 x 10 | 3.5 x 3.5 | 6 x 6 | 10 x 10 | 15 x 15 | 3.5 x 3.5 | 6 x 6 | 10 x 10 | 15 x 15 | |

| Rated Horsepower | 2.5 x 2.5 | 5 x 5 | 10 x 10 | 2.5 x 2.5 | 5 x 5 | 10 x 10 | 2.5 x 2.5 | 5 x 5 | 10 x 10 | 15 x 15 | 2.5 x 2.5 | 5 x 5 | 10 x 10 | 15 x 15 | |

| Compressor Type | Scroll | Scroll | Scroll | Scroll | |||||||||||

| Noise (dBa) | Heating | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Cooling | 68 | 75 | 75 | 68 | 75 | 75 | 68 | 75 | 75 | 75 | 68 | 75 | 75 | 75 | |

| Heating Elements (Kw) | 230/460 | 6 | 12 | 12 | 6 | 12 | 12 | 6 | 12 | 12 | 24 | 6 | 12 | 12 | 24 |

| 208V | 4.5 | 9 | 9 | 4.5 | 9 | 9 | 4.5 | 9 | 9 | 18 | 4.5 | 9 | 9 | 18 | |

| Model | ETCU–09 | ETCU–16 | ETCU–30 | ETCU–64 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Rate (min) | ||||||||||||||

| 190°C to -65°C | 49 | 34 | 14 | 78 | 36 | 19 | 155 | 76 | 31 | 20 | 256 | 125 | 52 | 42 |

| 71°C to -65°C | 36 | 26 | 11 | 40 | 28 | 15 | 119 | 59 | 26 | 17 | 197 | 97 | 44 | 33 |

| 85°C to -40°C | 27 | 18 | 8 | 32 | 20 | 12 | 95 | 42 | 21 | 12 | 157 | 69 | 36 | 24 |

| Heating Rate (min) | ||||||||||||||

| -65°C to 190°C | 35 | 16 | 16 | 32 | 22 | 22 | 60 | 30 | 30 | 20 | 110 | 53 | 53 | 27 |

| -65°C to 71°C | 17 | 8 | 8 | 14 | 11 | 11 | 27 | 13 | 13 | 10 | 45 | 23 | 23 | 13 |

| -40°C to 85°C | 16 | 8 | 8 | 12 | 10 | 10 | 27 | 13 | 13 | 11 | 45 | 23 | 23 | 14 |

| Water Cooled | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| Air Cooled | Y | Y | Y | Y | Y | Y | Y | |||||||

| 208 / 230V 1Ph | Y | N/A | N/A | Y | N/A | N/A | Y | N/A | N/A | N/A | Y | N/A | N/A | N/A |

| 208 / 230V 3Ph | Y | Y | N/A | Y | Y | N/A | Y | Y | N/A | N/A | Y | Y | N/A | N/A |

| 460V 3Ph | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| Air Delivery (Blower HP) | .5 HP | (2) .5 HP | (2) .75 HP | (2) .75 HP | ||||||||||

| Airflow (CFM) | 750 | 1600 | 1600 | 1600 | ||||||||||

| Temp Unif. (Std Dev/9 Pt) | +/-0.5°C/+/-1°C | +/-0.5°C/+/-1°C | +/-0.5C/+/-1°C | +/-0.5C/+/-1°C | ||||||||||

| Temp Control | +/-0.3°C | +/-0.3°C | +/-0.3°C | +/-0.3°C | ||||||||||

- Single Stage Refrigeration Temperature Range: -35°C to 200°C

- Performance is based upon an empty chamber operating at 24°C (75°F) ambient air and may vary slightly at other ambient temperatures. Voltages below those listed may affect performance. All performance data is for 240 or 480V / 60Hz operation.

- Liquid Nitrogen is available as an option on all systems. When Liquid Nitrogen is provided, the heater KW is automatically upgraded to the maximum for that chamber size. Consult factory for current draw of any Liquid Nitrogen equipped chambers.

- Airflow circulation is based on blower wheel performance curves. Actual circulation rate will vary depending on the cooling option selected.

- Temperature uniformity Standard deviation from the mean, measured at –25°C and 100°C. 9 Point: Uniformity measured in accordance with ASTM E145 section 4 at temperatures of –25°C and 100°C.

- Test chamber performance may be affected by the addition of certain optional accessories.

- Chamber operation utilizing 50Hz power utility will derate performance approximately 17%

- It is Thermal Product Solutions' policy to constantly improve quality, features and performance. Thermal Product Solutions reserves the right to change specifications without notice.