SAFETY OPTIONS

FOR BATTERY TEST CHAMBERS

-

1. Chamber Pressure Alarm

- Standard - -

2. Pressure Relief Ports

- Standard - -

3. Explosion Venting (NFPA Compliant)

- Standard - -

4. Redundant Process Temperature High Limit

- Standard - -

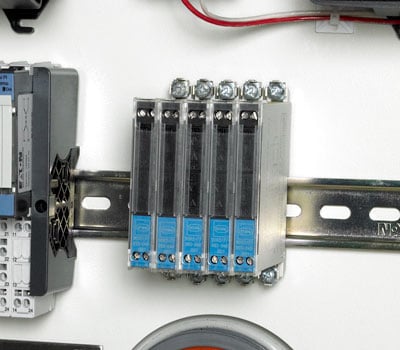

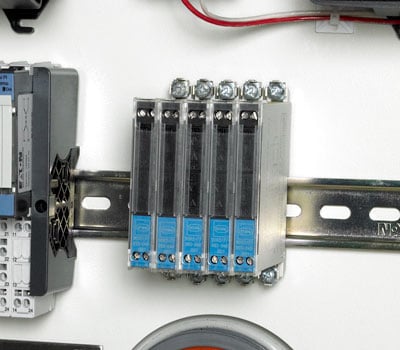

5. Intrinsic Safety Barriers

-

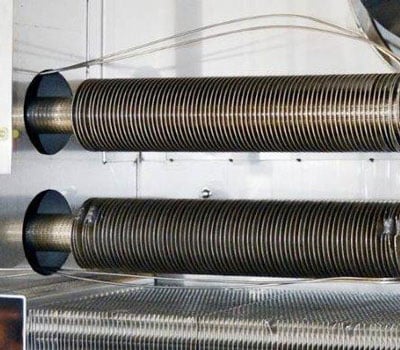

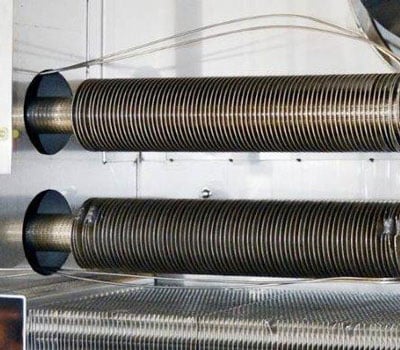

6. Temp Limited Electric Heaters

-

7. Emergency Stop

-

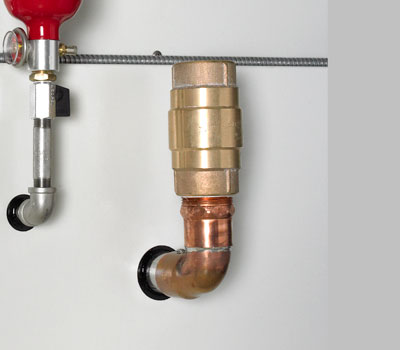

8. Rapid Purge System

-

9. NFPA Class "A" Ventilation System

-

10. Inert Atmosphere (NFPA Compliant)

-

11. Solvent Monitor (Hydrocarbons and solvents)

-

12. Gas Analyzers (H2, O2, CO2, CO)

-

13. Remote Shutdown

-

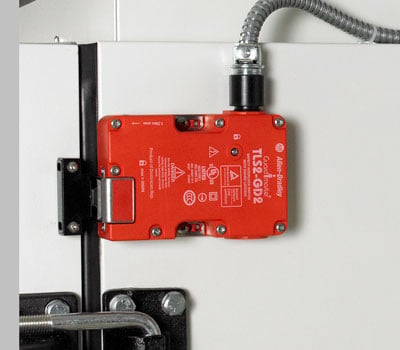

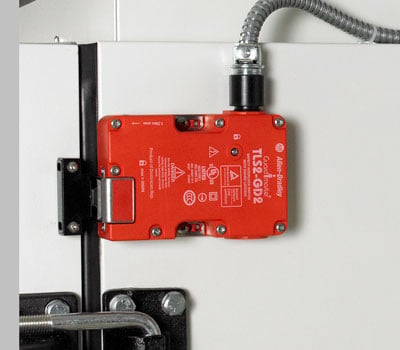

14. Automatic Door Locks

-

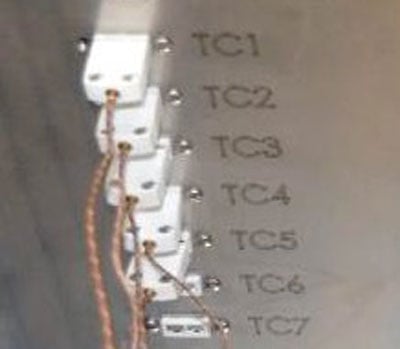

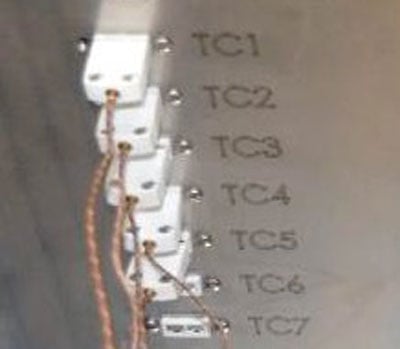

15. Product Monitoring Thermocouples

-

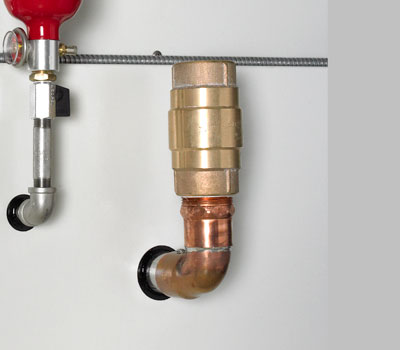

16. Rapid Cryogenic Cooling

-

17. Fire Suppression (Water, Halon, CO2, LN2)

-

18. Alarms (Audible, Visual, Output Contacts)

-

19. Heater Surface Temperature Limiters

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19