Tenney Classic Temperature / Humidity Cycling Test Chamber

Benefits

- Provides a wide range of temperature and humidity conditioning with many features for optimal tests

- Uses environmentally friendly, CFC-free refrigerants and durable refrigeration systems

- Hi-Lo pressure and oil pressure switches stop compressors from exceeding preset limit conditions, assuring safety of product and operator

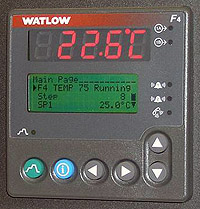

- Controllers feature advanced LCD display, allowing for fast and easy programming and configuration of the Tenney Classic Temperature / Humidity Test Chamber

Features

- Semi hermetic refrigeration system

- Vertical recirculation conditioning system

- Automatic defrost for door gaskets

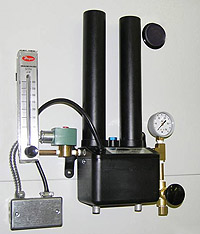

- Non-corroding parts on all humidity capable units

- Low water protection

- Open-air low mass nichrome wire heater elements supported by ceramic insulators

- Single stage or cascade refrigeration system

- Vapor-Flo I humidity generator (for capable units) with bell jar configuration

Performance

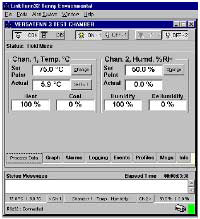

- Control accuracy: ±0.3°C and ±2% RH

- Standard humidity conditions: 20% to 98% RH in the dry bulb range from + 20° to + 85°C, as limited by a 3° dewpoint.

- Chamber models with a 'S' suffix indicate a single stage refrigeration system with one compressor.

- Temperature control range: -40°C to +200°C, ±0.3°C

- Chamber models with the 'C' suffix indicate a cascade refrigeration system and two compressors.

- Temperature control range: -73°C to +200°C, ±0.3°C

Controller

Options

Specifications

Tenney Classic Temperature / Humidity Cycling Test Chamber Specifications

40 and 64 cubic foot models

| Model | Non- humidified |

T40S-2 | T40C-2 | T40C-3 | T64S-7.5 | T64C-3 | T64C-7.5 |

|---|---|---|---|---|---|---|---|

| Humidified | T40RS-2 | T40RC-2 | T40RC-3 | T64RS-7.5 | T64RC-3 | T64RC-7.5 | |

| Workspace | W | 40(1016) | 48(1219) | ||||

| D | 44(1118) | 48(1219) | |||||

| H | 40(1016) | 48(1219) | |||||

| Exterior | W | 66(1676) | 72(1829) | ||||

| D | 73.5(1867) | 81.5(2070) | |||||

| H | 80.25(2038) | 91(2311) | |||||

.

| Temperature | Non- humidified |

T40S-2 | T40C-2 | T40C-3 | T64S-7.5 | T64C-3 | T64C-7.5 |

|---|---|---|---|---|---|---|---|

| Humidified | T40RS-2 | T40RC-2 | T40RC-3 | T64RS-7.5 | T64RC-3 | T64RC-7.5 | |

| Low | C | -40°C | -73°C | -73°C | -40°C | -73°C | -73°C |

| High | C | +200°C | +200°C | +200°C | +200°C | +200°C | +200°C |

| Humidity Capability | 20% to 98% RH in the dry bulb range of +20°C or +85°C as limited by a 3°C dew point. | ||||||

Test data based on 24°C ambient, sea level, 60Hz. On 50Hz or higher than 24°C, ambient performance may be reduced. Consult factory regarding any special cooling requirements.

| Change Rates in Minutes | |||||||

|---|---|---|---|---|---|---|---|

|

Time starting at Ambient to listed temperature. Based on empty chamber.

|

200°C

|

35 | 45 | ||||

|

150°C

|

25 | 30 | |||||

|

93°C

|

10 | 15 | |||||

|

65°C

|

5 | 10 | |||||

|

0°

|

5 | 5 | |||||

|

-18°C

|

20 | — | — | 10 | 10 | — | |

|

-40°C

|

120 | — | — | 25 | 30 | — | |

|

-54°C

|

— | 45 | 40 | — | 45 | 20 | |

|

-65°C

|

— | 60 | 50 | — | 65 | 35 | |

| Live Load Capacity in Watts (Humidity System Off) | |||||||

|---|---|---|---|---|---|---|---|

|

Temperature

|

+10°C | ||||||

| -18°C | 1000 | — | — | 4500 | — | — | |

| -40°C | 100 | — | — | 1000 | — | — | |

| -54°C | — | 1200 | 2000 | — | 1200 | 4000 | |

| -65°C | — | 900 | 1500 | — | 800 | 2500 | |

| Utilities, etc | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Refrigeration | (1) 2 HP | (2) 2 HP | (2) 3 HP | (1) 7.5 HP | (2) 3 HP | (2) 7.5 HP | |||||||

| Heater Capacity | 6 | 6 | 6 | 8 | 8 | 8 | |||||||

| Humidifier | KW | 2 | 2 | 2 | 2 | 2 | 2 | ||||||

| GPH | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | |||||||

| AMPS |

230V. 1Ph |

230V. 1Ph | 230V. 3Ph | 230V. 3Ph | 230V. 3Ph | 230V. 3Ph | |||||||

| S & C | RC & RS |

41 |

50 |

50 | 50 | 38 | 46 | 71 | 80 | 57 | 65 | 71 | 80 |

| Fuse |

50 |

60 |

60 |

60 | 60 | 70 | 100 | 110 | 70 | 80 | 100 | 110 | |

| Unit Weight | LBS. |

2740 |

3540 |

||||||||||