Tenney Industrial Blast Freezer

A leading international manufacturer of pharmaceuticals and medical products asked Thermal Product Solutions to design a chamber that would freeze blood plasma at a very accelerated pace while maintaining compliance with stringent international standards for Fresh Frozen Plasma, TPS answered the call by engineering a custom industrial blast freezer to meet the customer’s specific needs.

The new, Tenney Industrial Blast Freezer rapidly and safely freezes blood plasma, taking it from room temperature to -65 ⁰C in less than ten minutes. The chamber provides 12.5 cubic feet of workspace and accommodates two, stainless-steel inserts that each hold eight, 4.4-liter units of plasma, enabling the customer to freeze 16 units simultaneously. The chamber’s rapid freezing process provides temperature uniformity in every bag as well as optimal freezing efficiency, enabling the customer to transfer the freshly frozen product to a storage location and quickly begin a new processing cycle.

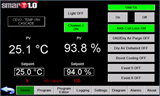

The blast freezer’s extremely low temperatures are attained through a cascade refrigeration system that uses two, 25-HP reciprocating compressors in a low stage/high stage design, with thermostatic expansion-valve-type refrigerant control. In the lower stage, a cascade condenser uses high-stage refrigerant to cool and condense low-stage refrigerant. A water-cooled condenser in the high stage changes hot, compressed, refrigerant gas into a liquid state to achieve specific heat-transfer functions. Cooling is accomplished though a high-volume air-delivery system and regulation of refrigerant flow to the chamber’s large evaporator-cooling coil. Four blower wheels with externally mounted motors generate the chamber’s 6,000 cubic-feet-per-minute, horizontal airflow.

Although the industrial blast freezer was built to meet the specific requirements of the manufacturer that requested it, Tenney is able to customize the chamber to accommodate other applications, configurations, footprints, and options.