Tenney Environmental announced the shipment of a Tenney Environmental Walk-In Chamber to the automotive industry. This chamber will be used to thermally test the insulation used in automobile interiors and will be subjected to different thermal conditions to test the R factor integrity.

This Tenney walk-in chamber maintains a relative humidity range of 20-95% in the temperature range of 20°C to 85°C limited by a 5°C dew point. The interior of the chamber has dimensions of 98” W x 196” D x 98” H. The operating temperature range is -68°C to 120°C with an overall maximum temperature of 150°C. The room will be capable of achieving 85°C and 94%RH.

“Many of our customers in the automotive industry have different needs for their Tenney equipment. This Tenney environmental walk-in chamber will be used for temperature cycling testing of composite material that will be used for automotive applications.” – Jason Cillo, International Sales Manager.

Unique features of this Tenney environmental test chamber include:

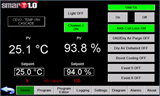

User-friendly LCD graphical 320 x 240 color display/touch screen programmer with simple English language prompts for program entry

Real time clock

Near infinite number of programs and steps

PID control with auto-tune and operator adjustable to match special chamber loading conditions (2-channel capability)

Tenney’s exclusive state of the art logic circuits automatically select the necessary refrigeration and heating capacities as well as humidification operating modes, as required to achieve the desired chamber environment

The controller incorporated communication capabilities for the “Connected Factory” of the future

Storage and retrieval of programs and test data from USB Port, local flash disk and/or removal PCMCIA flash card

Separate I/O controller (Olympic) for machine interface, machine diagnostics

RS-232 serial communications

Advanced Ethernet (10/100) communications capabilities using TCP/IP networking protocols

USB Port for data collection of set point temperature and actual for air temperature

Built in limit alarms

Flash disk on chip storage

Microsoft’s advanced Windows TM CE operating system

Serial communications are standard and wired externally to the cabinet with a DB9 port.

- Built in limit alarms including: High and Low Pressure for both refrigeration stages, high and low stage compressor safety module, conditioner fan motors, and the TGIV redundant over/ under temperature protection system

#133196